Filters Type

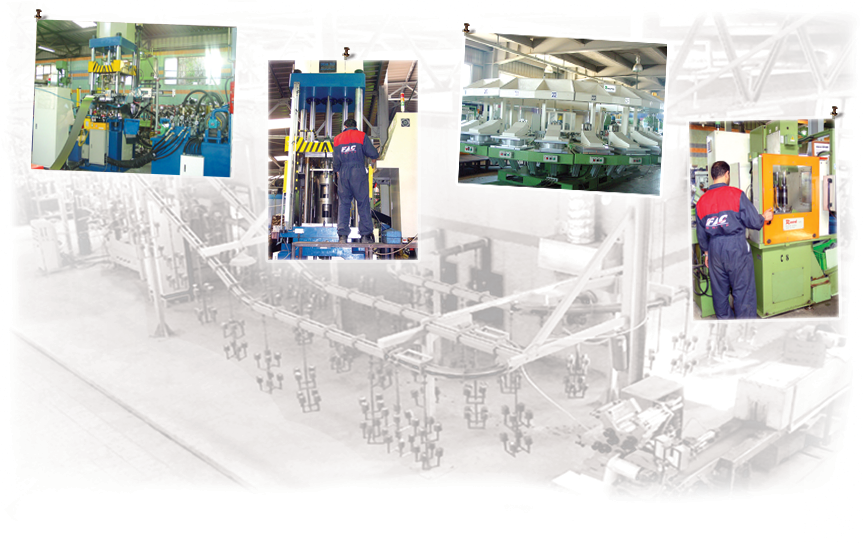

Manufacturing Facilities

- Continuously obtaining the new & modern technology in the field of filter fabrication.

- Using the most modern machines and equipment which maximizes both quality & quantity.

- FAC manufactures filters according to the international standards with the best and latest technology

FAC factory consists of three production units

-

Spin on filters facility for producing durable spin on oil and fuel filters with high technology deep drawing, forming special steel, and very efficient pleated paper. FAC uses automatic presses for producing filter housing body, and drum pleating machine to give a perfect pleated media which can withstand the applied high pressure.

-

Cartridge filters facility for producing oil and fuel filters with highly efficiently pleated paper, and high technology assembly system. This production unit can produce cartridge element for oil and fuel applications. Because the world trend is directed towards manufacturing products which are environment friendly, FAC started to manufacture ecology filters cartridge (ECO filters). ECO filters waste disposal problems are eased and the polymer has increased strength to prevent splitting. It is also economically viable and socially desirable.

- Air filters facility for producing all air filters types; heavy duty, panel and radial sealing. PU is a chemical mixture of two base components that gives a polymer base material that has its own compressibility. This prevents leakage and avoids mixing between filtered and non filtered air. An automatic mixer with highly tech system is desired in making perfect mixing ratios.